Results for Aerosol Treatment Technology Evaluation with Photocatalytic Device

September 4, 2021 Report

Experimental Approach

A standard EPA, ASHRAE, or ASTM-approved method does not currently exist for evaluating efficacy of aerosol treatment products or devices against bioaerosols. Utilizing EPA’s specialized Aerosol Test Facility in Research Triangle Park, NC and experience in conducting research with aerosolized biological agents, a standardized approach that can be applied across multiple technology types was developed to achieve the objectives of this project. An objective of the test conditions was to maintain a high enough concentration of viable aerosolized test virus in the air for 90 minutes in control conditions (without technologies active) to be able demonstrate a 3-log (99.9%) reduction in airborne virus concentration during test conditions (with technologies active) relative to the time-matched control tests. For these tests, MS2, a nonpathogenic bacteriophage that infects Escherichia coli, was used as the test virus.

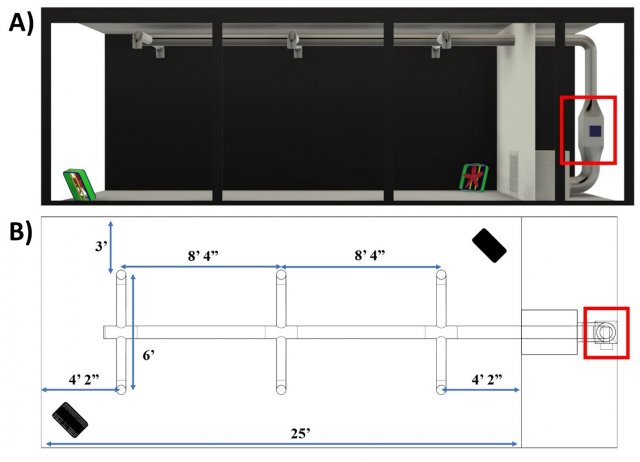

A large test section of the aerosol wind tunnel in EPA’s Aerosol Test Facility was sectioned off from the recirculating wind tunnel to serve as the test chamber utilized for this research. The 12 ft x 10 ft x 25 ft chamber provides a 3,000 ft3 conditioned space for dissemination and sampling of bioaerosols and for evaluating different aerosol treatment strategies (Figure 1). The chamber is temperature and relative humidity (RH) controlled, and its air is high-efficiency particulate air (HEPA)-filtered prior to each test. A mock heating, ventilation, and air conditioning (HVAC) system was designed and constructed in the test chamber to simulate air circulation and exchange rates typical of a wide range of general application settings. An Omni-Aire 1000V (Omnitec, Mukilteo, WA) negative air machine (NAM), with the HEPA filter removed, serves to represent a cold air return, recirculating air through the HVAC system and test chamber. A rectangular section downstream of the return serves as the installation section for aerosol treatment technologies. Air passing by the installed technology then flows through the 8-inch main duct before passing through six evenly spaced 6-inch branches that distribute air back to the chamber through 10-inch round diffusers with butterfly dampers at the distribution points. The system was constructed from galvanized steel materials, and the NAM airflow rate is set to 350 cubic feet per minute (CFM), resulting in approximately 7 air changes per hour (ACH) in the chamber. No outside air is introduced during testing. Two metal fans (LASKO 2265 QM, West Chester, PA) placed in opposite corners of the chamber facilitate mixing, operating at 1448 ft/min. In between tests, the chamber is opened, and recirculated HEPA-filtered air is run through the chamber until negligible particle counts are present in the air in preparation for the next test.

Figure 1. Test chamber schematics of A) side view and B) top-down view. The tested technology is installed in the rectangular section of the ductwork outlined in the red box.

The bacteriophage MS2 (ATCC 15597-B1), a non-enveloped virus that infects the host cell Escherichia coli (ATCC 15597), was used in this current study. Conducting research with aerosolized viruses at these large scales necessitates the use of safer, e.g., Biosafety Level (BSL)-1 potential surrogate viruses, versus using more pathogenic agents, such as SARS-CoV-2 (BSL-3). As a non-enveloped virus, MS2 is expected to be more resistant to chemical inactivation than enveloped viruses (e.g., SARS-CoV-2). MS2 stock is prepared using a top agar overlay technique, and samples are analyzed using a plaque assay with the E. coli host.

In this study, four 6-jet Collison Nebulizers (CH Technologies, Westwood, NJ) are used to aerosolize MS2 into the test chamber. In each nebulizer, a 10 mL mixture of 1:4 parts MS2 stock (MS2 in SM Buffer) to 0.22 μm filter-sterilized deionized water with 6 drops of Antifoam A (Sigma-Aldrich, St. Louis, MO) is nebulized over a period of 10 minutes prior to the first bioaerosol sampling period. Aerosolized MS2 is sampled using SKC BioSamplers (SKC Inc., Eighty-Four, PA) connected to air sampling pumps that draw air at a rate of 12.5 L/min. The sampling period for each aerosol sample is 10 minutes, resulting in a total volume of 125 L of air sampled during each sampling period. Bioaerosol samples are taken in duplicate from a 5 ft “breathing zone” height during each sampling period. The first aerosol sample in each test is taken immediately following the 10-minute aerosolization period (time = 0 sample). The count median diameter of aerosolized particles is 44 ± 2 nm at the beginning of each test (time = 0 min), and it increases over the duration of the test to 85 ± 3 nm at the end of 90 minutes, as measured by a Scanning Mobility Particle Sizer (Model 3080 Electrostatic Classifier/TSI 3022 Condensation Particle Counter, TSI Inc., Shoreview, MN).

Deposition of viable MS2 on surfaces and inactivation of MS2 on surfaces was also evaluated using uniform pieces of 2 cm x 4 cm stainless-steel material (coupons), which were prepared, cleaned, rinsed, and sterilized prior to testing. The deposition coupons were placed into the test chamber blank (i.e., clean, with no virus present prior to testing), and the inactivation coupons were inoculated with MS2 inoculum made in 5% Fetal Bovine Serum (FBS) with 1X phosphate-buffered saline (PBS) prior to being placed in the chamber. The two sets of coupons were co-located at five different locations on the chamber floor. The deposition coupons were placed inside the chamber to determine if the reduction of MS2 in the air was due to airborne inactivation or due to settling of viable virus particles.

RGF Photocatalytic Device Results

RGF® Environmental Group has developed a Photohydroionization® (PHI) technology that utilizes ultraviolet-C (UVC) light and a metallic catalyst to convert water vapor from the air into hydrogen peroxide and other reactive oxides and ions, which can then react with indoor air pollutants, including viruses. This technology was selected for evaluation based on prioritization from research stakeholders, including those in the transit industry. Two different units with 5” and 9” cells (the PHI-PKG5-24V and PHI-PKG9-24V models, respectively) were evaluated. The PHI-PKG5-24V is designed to operate with an HVAC blower size of 250-1200 CFM, and the PHI-PKG9-24V is designed to operate with an HVAC blower size of 1200-3000 CFM. The devices were each installed in-duct and operated continuously during testing (location noted in Figure 1). For the tests with the PHI-PKG5-24V, the device was operated for 30 minutes in the sealed chamber prior to aerosolization of MS2, and the PHI-PKG9-24V was operated for 5 minutes prior to MS2 aerosolization. Three different replicate tests were conducted with each unit. No hydrogen peroxide was detected during any of the tests (using a RKI SC-8000 with a hydrogen peroxide sensor; detection limit of 20 ppb). All testing was conducted at 22 ± 2 °C and a RH of 30-35%[1]. This RH was selected because virus viability is reduced at intermediate RH,[2] and an objective of the test design is to maintain sufficiently high concentration of viable aerosolized MS2 after 90 minutes that will allow for demonstration of a 3-log reduction in tests with technologies active relative to control conditions throughout the duration of each test.

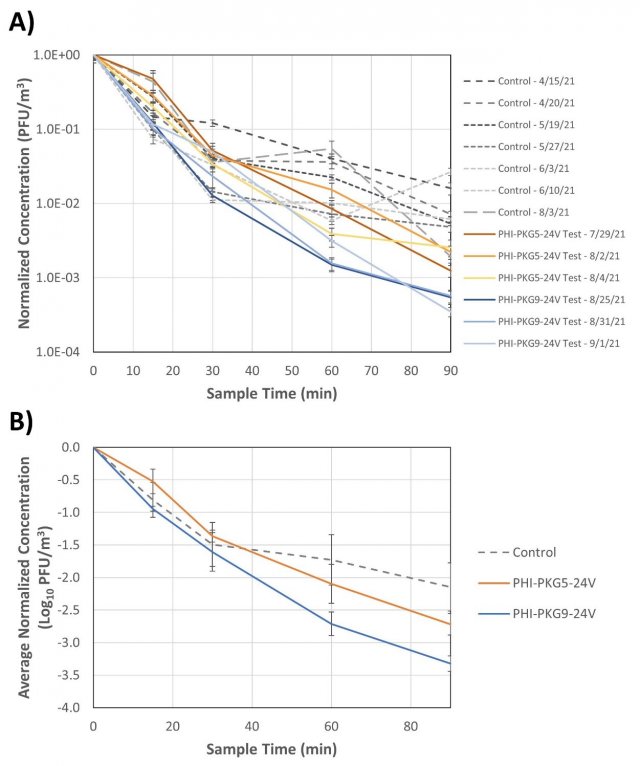

Figure 2 shows the concentration of MS2 at each sampling timepoint (normalized to the initial time = 0 min MS2 concentration) during each test. Seven control tests were conducted without the technology active three tests were conducted with the PHI-PKG5-24V device active, and three tests were conducted with the PHI-PKG9-24V device active.

Figure 2. A) Concentration of MS2 recovered from aerosol samples throughout the control and PHI Cell tests, normalized to the initial time = 0 min concentration for each test. Each timepoint represents recovery from duplicate bioaerosol samplers as determined by plaque assay, and the error bars represent pooled standard deviation at each sampling timepoint. B) Normalized log10 MS2 concentration at each sampling timepoint, averaged over each set of device tests and the controls. Error bars represent standard deviation in averaged MS2 recoveries for each test condition.

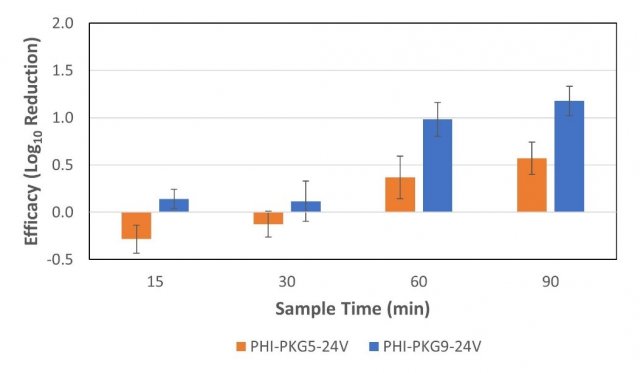

Figure 3 shows the log10 reduction in MS2, calculated by subtracting the average of the device test recoveries from the average of the control recoveries at each sampling timepoint. The average percent reduction in log10 recoveries at each sampling timepoint ranges from <0% (time = 15 min) to 73% (time = 90 min) for the PHI-PGK5-24V unit and from 27% (time = 15 min) to 93% (time = 90 min) for the PHI-PKG9-24V unit.

Figure 3. The calculated log10 reduction at each testing timepoint between the average recoveries of MS2 from the control tests and device tests. Error bars represent pooled standard error from the test and control experiments.

No significant differences were noted between MS2 recovered from the deposition coupons that were located throughout the chamber with either device active relative to control conditions, and the MS2 recoveries from inoculated coupons included in the device tests showed no reduction relative to control tests.

[1] EPA recommends that indoor relative humidity be maintained between 30% and 50% (https://www.epa.gov/iaq-schools/moisture-control-part-indoor-air-quality-design-tools-schools).

[2] Lin, Kaisen, and Linsey C. Marr. 2020. "Humidity-Dependent Decay of Viruses, but Not Bacteria, in Aerosols and Droplets Follows Disinfection Kinetics." Environmental Science & Technology 54 (2):1024-32. doi: 10.1021/acs.est.9b04959.