EPA’s SBIR Addresses Climate Change

Understanding and addressing climate change is critical to EPA's mission of protecting human health and the environment. Many of the observed changes in the Earth’s climate—such as rising temperatures, shifting precipitation patterns, and more extreme weather events—are linked to the rising levels of carbon dioxide (CO2) and other greenhouse gases in the atmosphere. Greenhouse gases from human activities have been the most significant driver of observed climate change since the mid-20th century. They build up in the atmosphere and warm the planet, which causes many changes in the climate around the world, and they remain in the atmosphere for many years after being released, affecting both present and future generations.

Through its Small Business Innovation Research (SBIR) program, EPA supports the development of new science and technology that addresses the EPA’s mission to protect human health and the environment. Climate change is a clear threat to human and environmental health, so projects that address some of the many aspects of climate change are a major focus of EPA’s SBIR support. All technologies funded by the EPA SBIR program use a lifecycle approach to account for energy use and carbon emissions that affect climate change. Here we highlight six small businesses funded by the EPA SBIR program to develop and commercialize technologies to address climate change.

Bridger Photonics (Bozeman, MT) - Remote gas sensing

EPA regulates carbon dioxide (CO2) emissions under the Clean Air Act. Regulation requires monitoring a wide variety of pollution sources, but no technology currently exists that can remotely measure and pinpoint the location of elevated CO2 concentrations. To address this issue, Bridger Photonics, Inc., developed a laser-based remote gas sensor prototype. First, Bridger created a laser source at the 2-μm wavelength, where the CO2 absorption strength is ideal for high spatial resolution concentration measurements. Thanks to EPA’s Commercialization Supplement, Bridger was able to develop a compact and efficient mid-infrared laser that can operate at wavelengths between 1.4 and 4 μm, allowing the detection of methane, as well as CO2. The technology can be used at a distance allowing personnel to simply point the sensor toward an emission stack, for example. The prototype gas sensor was successful at detecting CO2 concentrations with about 100 parts per million (ppm) sensitivity beyond 50 meters, which is a far lower concentration than the 5,000 ppm CO2 in an average human breath. Marketing this product without the gas sensor for laser ablation applications has already yielded more income than EPA invested.

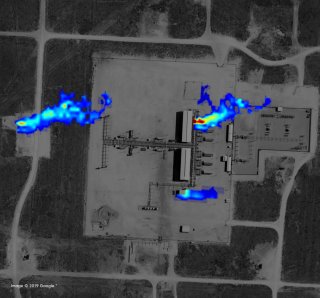

Bridger also developed a remote method to locate and quantify leaks across the oil and gas supply chain. The sensor technology is able to identify methane gas leaks and infrastructure changes in oil and gas facilities and pipelines. The sensor is able to provide high-resolution 3D maps and methane gas concentration imagery to detect, locate, and quantify regions of elevated methane concentration and associated leak rates. The 3D data also are available to assess equipment status, measure physical dimensions, and uncover right-of-way encroachment, erosion, or vegetation overgrowth.

Framergy (Wilmington, DE) – Natural gas and VOC recovery

Another area of pollution across the oil and gas supply chain is the use of continuous or intermittent venting and flaring, which emits methane and volatile organic compounds (VOCs). VOCs also can be lost throughout the network as oil and gas are transported and distributed over great distances. Framergy, Inc., designed a combination of VOC-philic solvents and novel metal-organic framework (MOF) adsorbents targeted to capture a wide range of volatile products and light hydrocarbons before they are vented into the atmosphere. This technology is capable of separating, storing and recycling natural gas and VOCs. Testing showed that the technology was suitable for both portable temporary use and permanent installation, which will allow it to be used at a wide range of facilities. Framergy has received third party investment and will use the funds for a prototype and demonstration unit to advance the scale and market readiness of the VOC capture technology. The technology is in negotiations to be piloted at a gas operations center of an oil and gas services company who are also interested in the commercial viability of the technology.

Providence Photonics (Baton Rouge, LA) – Flare combustion efficiency measurement

The flares used in the oil and gas industry emit significant amounts of VOCs and greenhouse gases (GHGs) and no practical methods exist to directly measure the combustion efficiency of flares and provide real-time feedback to reduce flare emissions. Inaccuracies and variations in current methods can cause significant errors in air quality planning, health impact assessments, and greenhouse gas inventory. Providence Photonics, LLC, developed a new instrument and method called Video Imaging Spectral Radiometer (VISR) to remotely measure flare combustion efficiency in real time. The VISR uses a multi-spectral infrared imager to measure relative concentrations of unburned hydrocarbons and combustion products, such as CO2, to determine the combustion efficiency. This technology has a significant impact on the flare industry, providing the flare operator with the tools to accurately measure flare performance and optimize flare efficiency. This allows the operator to minimize emissions from flaring, which also will reduce the cost of complying with existing and new regulations. The technology has been deployed to hundreds of flares at both onshore and offshore facilities all over the world and has become the de facto reference method for measuring flare performance. EPA has used the technology for flare inspections to ensure proper flare operations by various industrial facilities. A new measurement model is more suitable for upstream and midstream applications and can directly measure methane emissions from flares at distances up to 1,000 feet. Both the original and new model play a unique role to fill the technological gap in measuring, rather than estimating, methane emissions as required by the oil and gas industry’s global initiatives to reduce methane emissions.

Industrial Microbes (Alameda, CA) – Chemicals from methane

SBIR companies have also addressed other aspects of the fossil fuel industry. Industrial Microbes, Inc., developed a way to replace carbon-emitting petrochemical production with newer methods that build chemicals out of methane and CO2. Traditional chemical production is a major source of carbon pollution, but many chemicals could be produced from the least expensive carbon sources possible: methane generated from waste systems. The challenges of working with natural methane-consuming bacteria previously prevented the commercialization of fermenting methane into chemicals, so Industrial Microbes has been engineering Escherichia coli, commonly used in large-scale fermentation, to consume methane. The project focused on producing fatty acids, which are used widely but currently are made from unsustainable palm oil. Methane assimilation genes were combined with fatty acid production genes in a single host organism, and the metabolic pathway was adjusted. Industrial Microbes’ innovative microbe and biomanufacturing platform will support fatty acid production in a diverse set of applications. Industrial Microbes secured $2 million in private investment to extend the work funded by EPA SBIR to include other chemicals that can be made with methane and CO2. They were also named one of Biofuel Digest’s Next 50 Companies to Disrupt the World which recognizes bioeconomy companies that are working commercialize an emerging technology. “The EPA has been an incredible supporter of our efforts to help decarbonize the chemicals industry,” said Derek Greenfield, CEO and PI on the project.

Lucid Design Group (formerly Oakland, CA) – Energy use feedback software

As the climate on this planet changes, the way people use and think about energy is changing as well. Lucid Design Group, Inc., developed a system that uses off-the-shelf, multicolored, internet-connected LEDs to encourage people to conserve energy in commercial buildings. Lucid’s software and LED lights were combined into “Building Orbs” that use real-time electricity usage data to change the ambient color of the lights to show building occupants how much energy they are using. Lucid anticipated that individual occupants of commercial buildings, rather than facility managers, would have more and more control of their energy usage over time through behavior, so connecting people to their energy use on an individual level will become even more important for conservation. Lucid developed its technology into BuildingOS® business intelligence platform – used by more than 500 customers and providing analytics for more than 15,000 buildings. Lucid is now part of Atrius, a brand within the Intelligent Spaces Group at Acuity Brands.

Ecovative Design (Albany, NY) – Mushroom Materials

Earth’s resources are used even in ways that many people might not be aware of—for example, the United States consumes a significant amount of fossil fuels to make commonplace items like plastic products and foam packaging materials, which are difficult to recycle and have non-biodegradable constituents that eventually concentrate in the tissues of humans and other organisms. Ecovative Design, LLC, addressed this by developing a sustainable biomaterial to replace these synthetic materials that is made of agricultural byproducts bound by a natural resin grown out of mycelium, a filamentous fungus. After testing a number of agricultural options, Ecovative selected a composite made of plant stalks and seed hulls as the strongest material for insulating panels. The panels bound with mycelium were comparable to or outperformed the synthetic polystyrene panels in testing and can be introduced into the current market at a price point comparable to synthetic foams. Ecovative has had significant commercial success in adapting their biomaterial for multiple applications including packaging, construction materials and furniture, and they recently spun out Atlast Food Co. using mycelium as a super ingredient in plant-based meats. Their next market focus is producing mycelium-based leather alternatives that are vegan and free of plastics. Ecovative’s products are available in 32 countries, and the company’s major clients include Ikea, Dell and Crate & Barrel. Ecovative has also brought in sizable outside investments, including a $60M Series D financing round.

EPA is committed to addressing climate change and the harmful effects that it has on the environment and human health. Through its SBIR program, EPA supports projects that will generate and improve methods by which the many complex aspects of climate change, including the emission of greenhouse gases and the use of fossil fuels, are addressed. With these new methods and technologies, EPA can build on its successes in reducing the effects of climate change and bolster its overall mission to protect human health and the environment.